Intelligent handheld terminal helps build smart factory

2023.04.07

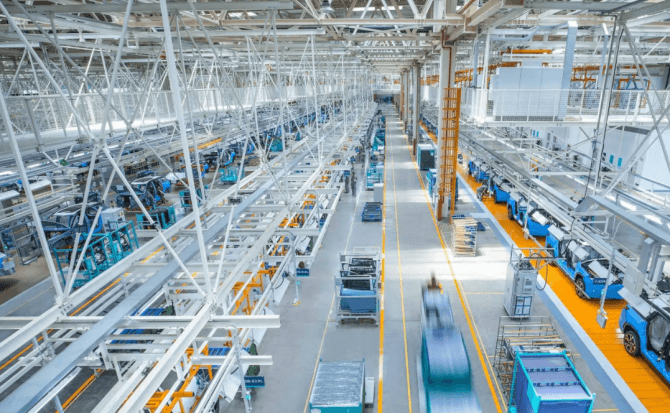

Smart factory is the new trend of the development of manufacturing industry in the future, and also the only way for the transformation and development of manufacturing industry. The state encourages and supports manufacturing enterprises to develop in the direction of smart factory. The so-called smart factory, in short, is to make the overall production process more intelligent on the basis of the original factory. The production process of smart factory mainly includes production operation, storage operation, inventory tracking, product quality, equipment maintenance, environment, etc.

Traditional factories have problems such as inefficient information management, poor quality control and non-visualization of production. All these are difficult problems affecting the transformation and upgrading of traditional factories. The emergence of intelligent handheld terminals in the Internet of Things has accelerated the upgrading and transformation process of traditional factories.

1. Production process visualization

The traditional factory production process adopts extensive production mode, and the production process is complex. If manual paper records are used, errors and omissions are easy to occur, and the production plan standard efficiency is low, which affects the product quality. The use of intelligent handheld terminal can replace paper verification, timely scanning code records, fine to every step of production, scientific supervision, management more efficient.

2. Intelligent storage management

Traditional factory warehouse management is disordered, all kinds of materials are still in accordance with the traditional pasted paper labels and manual verification, but this management is easy to lead to slow shipment efficiency, leaving a bad impression on customers. The use of intelligent handheld terminal can realize the material and product directly scan code for inventory, quickly read the information, convenient warehousing and warehousing, but also can realize the data information synchronization to the computer. In addition, the use of smart handheld terminals, but also can reduce the warehouse staffing, thus reducing the plant's operating costs.

3. Product tracking and tracing

One thing one code, to achieve product traceability, product quality problems traceability. For the products that have been shipped out, the date, model, color and production number of the goods are recorded through the barcode or two-dimensional code, and the operators can use the handheld terminal to read the information, which can be directly traced back to the source in the first time. For some unqualified production batches of goods, you can also mark and upload information to the background through the handheld terminal, make remarks for unqualified batches, timely recovery, timely destruction.

The N40 industrial-grade handheld terminal of Blovedream Technology comes with physical buttons, which is convenient for manual data input. It adopts Android 10.0 system, is equipped with octagonal processor, and has 2G+16G memory and 4G+64G memory to choose from. The overall device runs smoothly and users are more convenient to use. Smart handheld terminals facilitate the development of smart factories with convenient and efficient features.

Relevant recommendation

National Service Hotline

+0086 0755-26072520

Company Address: 17th Floor, Building B, Fencheng Zhigu Building, No. 60, Tiezai Road, Gongle Community, Xixiang Street, Bao'an District, Shenzhen

Wechat QR Code

Alibaba Shop

copyright © 2022 Shenzhen BLOVEDREAM Technology Co., Ltd Guangdong ICP No. 20027642